This article provides essential insights and strategies for the proper storage and maintenance of backup gate valves, ensuring their longevity and optimal performance in various applications.

Understanding the significance of proper storage can prevent damage and extend the lifespan of backup gate valves. Inadequate storage practices can lead to issues such as corrosion, physical damage, and mechanical failure. By ensuring that these valves are stored correctly, you can mitigate risks that could compromise their functionality.

Implementing best practices in storage can significantly enhance the durability of backup gate valves. Below are key steps to ensure safe and effective storage:

- Choosing the Right Environment

- Utilizing Proper Packaging

- Labeling Clearly

The environment in which backup gate valves are stored plays a crucial role in their longevity. Ideal conditions include:

- Temperature: Maintain a consistent temperature to prevent material degradation.

- Humidity: Control humidity levels to avoid corrosion.

Maintaining appropriate temperature levels is essential to prevent material degradation. The recommended temperature range for safe storage of gate valves is between 10°C to 30°C. Extreme temperatures can weaken the materials, leading to premature failure.

Excess moisture can lead to corrosion and damage. Utilize dehumidifiers or silica gel packs in storage areas to manage humidity effectively. Aim for a humidity level below 50% to protect the valves.

Proper packaging and labeling are vital for the organization and protection of backup gate valves. Use sturdy materials such as cardboard boxes or plastic wraps to shield valves from dust and moisture. Ensure that each package is clearly labeled with pertinent information, including the valve type, size, and storage date.

Regular maintenance is crucial for ensuring that backup gate valves function effectively. Here are essential maintenance practices:

- Routine Inspection Procedures

- Cleaning and Lubrication Techniques

Conducting regular inspections can help identify potential issues before they escalate. Check for signs of wear, leakage, or corrosion during each inspection. Schedule these inspections at least twice a year to ensure valves remain in optimal condition.

Keeping backup gate valves clean and well-lubricated is essential for their performance. Use a soft cloth to clean the exterior and apply appropriate lubricants to moving parts. Avoid using harsh chemicals that could damage the valve materials.

Avoiding common mistakes can significantly improve the effectiveness of storage practices. Here are frequent pitfalls to steer clear of:

- Neglecting Environmental Factors

- Improper Handling and Transportation

Failing to consider environmental factors can lead to premature valve failure. Monitor storage conditions regularly to ensure they remain within the recommended parameters.

Handling and transporting backup gate valves incorrectly can cause damage. Always use appropriate lifting techniques and transport valves in padded containers to prevent impacts.

Recognizing when to replace backup gate valves is crucial for system reliability. Look for the following signs of wear:

- Visible corrosion

- Difficulty in operation

- Frequent leaks

When replacement is necessary, knowing your options is critical. Various types of backup gate valves are available in the market, each suitable for different applications. Consult with a specialist to choose the best valve for your needs.

Why is Proper Storage Important for Backup Gate Valves?

Proper storage of backup gate valves is a critical aspect of ensuring their longevity and functionality. Understanding the significance of proper storage can prevent damage and extend the lifespan of these essential components. This section highlights the risks associated with inadequate storage practices, emphasizing the need for a well-planned storage strategy.

One of the primary risks of improper storage is corrosion. When gate valves are stored in damp or humid environments, moisture can accumulate, leading to rust and deterioration of the metal components. This not only compromises the integrity of the valves but can also result in costly repairs or replacements. To mitigate this risk, it is crucial to store gate valves in a controlled environment where humidity levels are monitored and maintained.

Another significant concern is physical damage. Inadequate packaging or careless handling can lead to dents, scratches, or other forms of damage that affect the valve’s performance. For instance, if valves are stacked improperly or exposed to heavy objects, they may become misaligned or suffer structural harm. To avoid these issues, it is essential to use appropriate packaging materials and ensure that valves are securely stored in a manner that prevents movement and impact.

Furthermore, exposure to extreme temperatures can adversely affect the materials used in backup gate valves. High temperatures may cause seals and gaskets to degrade, while low temperatures can lead to brittleness in some materials. Therefore, it is vital to store these valves within the recommended temperature range to preserve their functionality and prevent premature failure.

In addition to environmental factors, contamination poses another risk during storage. Dust, dirt, and other particles can enter the valve’s internal mechanisms, potentially leading to blockages or malfunction. To prevent contamination, valves should be stored in clean, dust-free environments, and openings should be covered or sealed when not in use.

Finally, inadequate inventory management can lead to misplacement or loss of valves, complicating maintenance and replacement efforts. Implementing a proper labeling system and maintaining an organized storage space is essential for easy retrieval and tracking of backup gate valves.

In summary, understanding the importance of proper storage for backup gate valves is crucial in preventing corrosion, physical damage, temperature-related issues, contamination, and misplacement. By adopting best practices in storage, users can significantly enhance the lifespan and performance of their backup gate valves, ensuring they remain reliable components in various applications.

What Are the Best Practices for Storing Backup Gate Valves?

When it comes to maintaining the integrity and functionality of backup gate valves, implementing best practices in storage is crucial. Proper storage not only enhances their durability but also ensures they perform optimally when needed. This section details the essential steps to guarantee safe and effective storage of these vital components.

To maximize the lifespan of backup gate valves, consider the following best practices:

- Choose the Right Environment: The storage environment is fundamental. Ideally, backup gate valves should be stored in a clean, dry, and temperature-controlled area. This helps mitigate the risk of corrosion and material degradation.

- Maintain Temperature Control: It is essential to keep the storage temperature within a specified range. Most gate valves perform best when kept at temperatures between 50°F and 80°F. Extreme temperatures can cause the materials to expand or contract, leading to potential failures.

- Manage Humidity Levels: Excessive humidity can lead to rust and corrosion. Use dehumidifiers or silica gel packets in storage areas to maintain ideal humidity levels below 50%. Regularly check humidity levels to ensure they remain stable.

- Utilize Proper Packaging: Packaging plays a vital role in protecting backup gate valves during storage. Use water-resistant materials and ensure that each valve is individually wrapped to prevent scratches and damage.

- Labeling: Clearly label each package with essential information such as the type of valve, size, and date of storage. This practice aids in quick identification and retrieval, reducing the risk of mishandling.

By adhering to these best practices, you can significantly enhance the durability and reliability of backup gate valves, ensuring they remain in optimal condition for future use.

Understanding the importance of proper storage for backup gate valves cannot be overstated. Improper storage can lead to several issues, including:

- Corrosion: Exposure to moisture can lead to rust and corrosion, which can compromise the valve’s integrity.

- Material Degradation: High temperatures may cause materials to warp or weaken, leading to potential failures during operation.

- Increased Replacement Costs: Neglecting proper storage can result in frequent replacements, significantly increasing maintenance costs.

By recognizing these risks, it becomes clear that investing time and resources into proper storage practices pays off in the long run.

To further enhance the effectiveness of your storage practices, avoid the following common mistakes:

- Neglecting Environmental Factors: Failing to monitor temperature and humidity can lead to unforeseen damage.

- Improper Handling: Always handle backup gate valves with care. Dropping or mishandling them during storage can result in physical damage.

- Overlooking Packaging: Using inadequate packaging can expose valves to environmental hazards, leading to deterioration.

By steering clear of these pitfalls, you can ensure that your backup gate valves remain in excellent condition, ready for use when necessary.

Choosing the Right Environment for Storage

When it comes to the longevity and functionality of backup gate valves, the storage environment is a critical factor that should not be overlooked. This section delves into the ideal conditions that ensure these essential components remain in optimal condition, focusing on both temperature and humidity levels.

Temperature plays a vital role in maintaining the integrity of backup gate valves. It is recommended to store these valves in a controlled environment where the temperature ranges from 15°C to 25°C (59°F to 77°F). Extreme temperatures, whether hot or cold, can lead to material degradation, affecting the valve’s performance. For instance, high temperatures can cause rubber seals to harden, while low temperatures can make materials brittle. Therefore, maintaining a stable temperature is essential for preserving the quality of the valves.

Humidity is another crucial environmental factor. Excessive moisture in the air can lead to corrosion and rust, which can severely damage the valves. Ideally, the humidity level should be kept below 60%. To manage humidity effectively, consider using dehumidifiers or silica gel packets in storage areas. Regularly monitoring humidity levels with hygrometers can also help in maintaining the right conditions.

Good ventilation is essential in storage areas for backup gate valves. Stagnant air can trap moisture and create an environment conducive to corrosion. Ensuring adequate airflow helps in keeping the storage area dry and reduces the chances of moisture accumulation. Ideally, storage spaces should be well-ventilated, allowing for air circulation that keeps humidity levels in check.

In addition to temperature and humidity, other environmental factors such as light exposure and dust accumulation should also be taken into account. Direct sunlight can degrade certain materials used in gate valves, while dust can interfere with their operation. Thus, it is advisable to store backup gate valves in a dark, clean environment, preferably covered or in a sealed container.

- Use Protective Covers: Always cover valves with protective materials to shield them from dust and moisture.

- Label Storage Containers: Clearly label all storage containers to identify the contents easily, preventing confusion and ensuring proper handling.

- Regular Inspections: Conduct routine checks to assess the condition of stored valves, ensuring they remain free from damage and corrosion.

By adhering to these guidelines and maintaining the right storage environment, you can significantly enhance the lifespan and performance of backup gate valves. Proper care and attention to environmental conditions will not only prevent premature failures but also ensure that these critical components are ready for use when needed.

Temperature Control

Maintaining appropriate temperature levels is essential to prevent material degradation and ensure the longevity of backup gate valves. The integrity of these valves can be compromised if they are stored in environments that do not adhere to recommended temperature ranges. This section outlines the ideal temperature conditions for safe storage, emphasizing the importance of consistent monitoring and control.

To maintain the functional quality of backup gate valves, it is crucial to store them within a specific temperature range. Generally, the ideal temperature for storing gate valves is between 10°C to 30°C (50°F to 86°F). This range helps to minimize the risk of thermal expansion and contraction, which can lead to structural weaknesses.

Temperature fluctuations can cause significant damage over time. High temperatures can accelerate the degradation of materials, especially rubber seals and gaskets, while low temperatures may lead to brittleness in certain types of plastics and metals. Regular monitoring of the storage environment is necessary to ensure that the temperature remains within the recommended range.

Implementing effective temperature control strategies is vital for the safe storage of gate valves. Here are several practical steps to consider:

- Use Climate-Controlled Storage: If possible, utilize climate-controlled facilities that can maintain a consistent temperature.

- Install Temperature Sensors: Use sensors that provide real-time data on temperature levels, allowing for immediate action if conditions deviate from the norm.

- Regular Inspections: Conduct routine checks on the storage area to ensure that temperature levels remain stable.

Improper temperature management can lead to a variety of issues, including:

- Corrosion: Excessive heat can cause moisture to accumulate, leading to rust and corrosion.

- Material Failure: Prolonged exposure to temperatures outside the recommended range can weaken the valve structure, leading to potential failures during operation.

- Increased Maintenance Costs: Valves that have suffered damage due to improper storage may require more frequent maintenance or even complete replacement, increasing operational costs.

To ensure the longevity and performance of backup gate valves, it is essential to adopt best practices for temperature control:

- Keep the Area Clean: A clean storage area helps to prevent dust and debris from interfering with temperature control systems.

- Insulation: Use insulation materials to help maintain stable temperatures, especially in regions with extreme weather conditions.

- Document Temperature Logs: Keeping a record of temperature readings can help identify patterns and potential issues over time.

By adhering to these guidelines, you can significantly reduce the risk of damage to backup gate valves caused by temperature fluctuations. Proper temperature control not only enhances the lifespan of the valves but also ensures their reliable performance in critical applications.

Humidity Management

Effective is crucial in maintaining the integrity and functionality of backup gate valves. Excess moisture in storage environments can lead to corrosion, which compromises the performance and lifespan of these essential components. This section delves into strategies that can be implemented to control humidity levels and protect your valves from potential damage.

High humidity levels can create an environment conducive to rust and corrosion, particularly for metal components. When moisture accumulates, it can lead to the formation of oxidation on the surface of the valves, resulting in deterioration over time. Understanding this relationship is the first step in mitigating risks associated with moisture.

- Use of Dehumidifiers: Investing in dehumidifiers can significantly reduce moisture levels in storage areas. These devices are particularly effective in enclosed spaces where air circulation is limited.

- Ventilation: Ensure that the storage area is well-ventilated. Proper airflow helps to dissipate moisture and maintain a stable environment. Consider installing vents or using fans to enhance air circulation.

- Humidity Monitoring: Utilize hygrometers to monitor humidity levels regularly. Keeping track of these levels allows for timely interventions when humidity rises above acceptable thresholds.

- Desiccants: Incorporate desiccants, such as silica gel, in storage containers. These materials absorb excess moisture and help maintain a dry environment around the valves.

- Regular Maintenance: Conduct routine inspections of the storage area to identify any leaks or sources of moisture. Addressing these issues promptly can prevent humidity-related damage.

The location where backup gate valves are stored plays a significant role in humidity management. Ideally, select a storage area that is cool and dry, away from sources of moisture such as bathrooms, kitchens, or outdoor walls. A climate-controlled environment is preferable, as it allows for consistent temperature and humidity levels.

Proper packaging can also aid in humidity management. When storing backup gate valves, consider the following:

- Sealed Packaging: Use airtight containers or vacuum-sealed bags to protect valves from moisture exposure.

- Corrosion-Resistant Coatings: Apply protective coatings to the valves before storage. These coatings create a barrier against moisture and can significantly reduce the risk of corrosion.

In summary, effective humidity management is essential for the preservation of backup gate valves. By implementing strategies such as using dehumidifiers, ensuring proper ventilation, and employing appropriate packaging techniques, you can significantly enhance the longevity and performance of these vital components. Regular monitoring and maintenance will further ensure that your storage environment remains optimal, safeguarding against the detrimental effects of humidity.

Utilizing Proper Packaging and Labeling

Proper packaging and labeling are vital for the organization and protection of backup gate valves. The right materials and practices not only safeguard these essential components but also enhance their usability and accessibility when needed. In this section, we will explore the best strategies for packaging and labeling backup gate valves, ensuring they remain in optimal condition during storage and transport.

Why is Packaging Important for Backup Gate Valves?

Effective packaging protects backup gate valves from physical damage, moisture, and contaminants. Using appropriate materials can significantly reduce the risk of corrosion and wear, which can compromise the functionality of the valves. Moreover, well-packaged valves are easier to handle and transport, minimizing the chances of mishaps.

What Materials Should Be Used for Packaging?

- Plastic Wrap: This is ideal for providing a moisture barrier. It helps in preventing rust and corrosion.

- Bubble Wrap: When cushioning is required, bubble wrap is an excellent choice. It absorbs shocks during handling and transportation.

- Cardboard Boxes: Sturdy cardboard boxes can be used for bulk storage. They provide structural support and are easy to label.

- Desiccants: Including desiccants in the packaging can help manage humidity levels, further protecting the valves from moisture damage.

How to Label Backup Gate Valves Effectively?

Labeling is just as important as packaging. Proper labels help in quick identification and retrieval of backup gate valves when needed. Here are some best practices:

- Use Clear Fonts: Labels should be printed in a clear, legible font to avoid confusion.

- Include Essential Information: Each label should contain vital details such as the valve type, size, and any specific handling instructions.

- Color Coding: Implementing a color-coding system can help in quickly identifying different types of valves or their respective applications.

- Durable Materials: Labels should be made from waterproof and tear-resistant materials to withstand various environmental conditions.

Best Practices for Packaging and Labeling

To ensure the longevity and optimal performance of backup gate valves, consider the following best practices:

- Inspect Before Packing: Always inspect valves for any signs of damage before packaging them. This step ensures that only functional valves are stored or transported.

- Seal Packages Securely: Ensure that all packages are sealed tightly to prevent any ingress of moisture or contaminants.

- Maintain Consistency: Use standardized packaging and labeling methods across your inventory to streamline processes and improve efficiency.

- Document Storage Locations: Keep a detailed inventory of where each valve is stored. This practice aids in quick retrieval and reduces the time spent searching for specific items.

By implementing these packaging and labeling strategies, organizations can significantly enhance the protection and organization of their backup gate valves, ensuring they remain in optimal condition for future use.

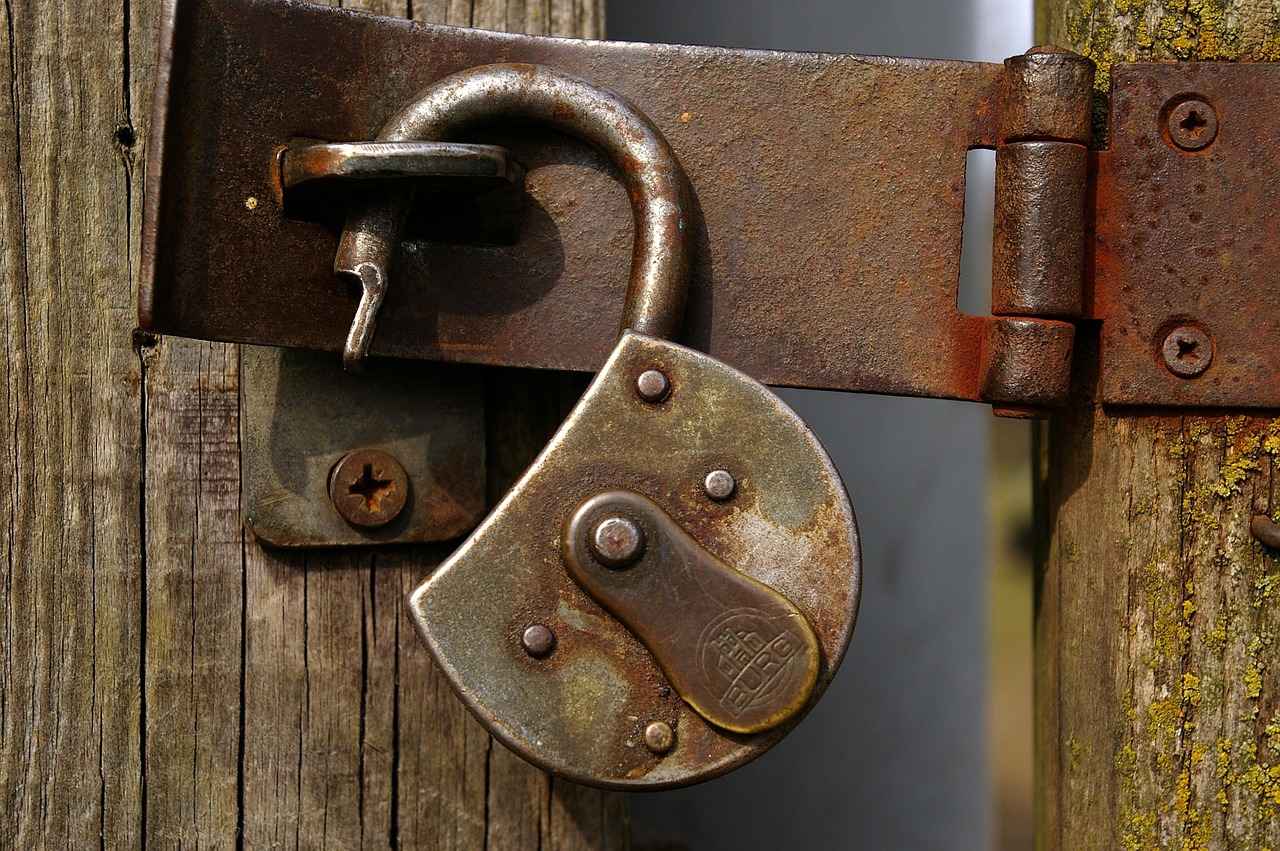

How to Maintain Backup Gate Valves for Optimal Performance?

Maintaining backup gate valves is essential for ensuring their optimal performance and longevity. These valves play a critical role in various systems, particularly in preventing backflow and maintaining pressure. Regular upkeep not only enhances their functionality but also minimizes the risk of costly repairs and replacements. In this section, we will delve into effective maintenance practices that can help keep your backup gate valves in top condition.

To ensure that backup gate valves function effectively, it is crucial to implement a comprehensive maintenance routine. Below are some essential practices:

- Routine Inspection: Regular inspections are vital for identifying potential issues before they escalate. Check for signs of wear, leaks, or corrosion. A systematic approach can help pinpoint problems early.

- Cleaning: Keeping valves clean is essential to prevent buildup that can hinder performance. Use non-corrosive cleaning agents and soft brushes to remove dirt and debris.

- Lubrication: Proper lubrication of moving parts is critical. Use suitable lubricants that are compatible with the valve materials to ensure smooth operation.

- Testing Functionality: Periodically test the valve’s operation to ensure it opens and closes smoothly. This can help identify any mechanical issues that may not be visible during a visual inspection.

The frequency of inspections can vary based on the application and environment. However, a general guideline is to perform inspections at least every six months. For valves in high-use or critical systems, consider more frequent checks. Documenting each inspection can help track performance over time and identify trends.

Avoiding common pitfalls can significantly improve the effectiveness of your maintenance practices. Here are some mistakes to watch out for:

- Ignoring Signs of Wear: Failing to address minor issues can lead to major failures. Always take note of any irregularities during inspections.

- Using Incorrect Cleaning Agents: Some cleaning agents can damage valve materials. Always refer to manufacturer guidelines for recommended products.

- Over-Lubrication: While lubrication is important, too much can attract dirt and debris, leading to further issues.

In addition to regular maintenance, proper storage is essential for preserving the integrity of backup gate valves. Store valves in a clean, dry environment, away from direct sunlight and extreme temperatures. Use protective covers to shield them from dust and moisture.

Implementing a regular maintenance schedule for backup gate valves offers numerous benefits:

- Enhanced Longevity: Regular care extends the lifespan of valves, reducing the need for premature replacements.

- Improved Performance: Well-maintained valves operate more efficiently, ensuring optimal system performance.

- Cost Savings: Preventative maintenance can save money by avoiding costly repairs and downtime.

By adhering to these maintenance practices, you can ensure that your backup gate valves remain in optimal condition, thereby enhancing the reliability and efficiency of your systems. Remember, proactive maintenance is key to preventing future issues and ensuring long-term performance.

Routine Inspection Procedures

Conducting regular inspections is a critical practice that plays a significant role in the maintenance of backup gate valves. By identifying potential issues early, you can prevent minor problems from escalating into major failures, which can be costly and disruptive. This section outlines the key inspection procedures that should be followed to ensure the optimal performance of backup gate valves.

Routine inspections are essential for several reasons:

- Early Problem Detection: Inspections can uncover signs of wear, corrosion, or other issues that may compromise the integrity of the valve.

- Performance Assurance: Regular checks ensure that the valves are functioning as intended, maintaining system efficiency.

- Cost Savings: By addressing potential issues early, you can avoid expensive repairs or replacements down the line.

To conduct effective inspections, consider the following procedures:

- Visual Inspection: Start with a thorough visual examination of the gate valves. Look for signs of rust, corrosion, or physical damage. Ensure that the valve body is intact and that there are no leaks present.

- Functional Testing: Perform functional tests to ensure that the valve opens and closes smoothly. This can involve operating the valve under normal conditions to check its responsiveness.

- Seal Integrity Check: Inspect the seals for any signs of wear or deterioration. Proper seal integrity is crucial for preventing leaks and maintaining pressure.

- Connection Verification: Check all connections to ensure they are secure. Loose fittings can lead to leaks and reduced performance.

- Documentation: Keep detailed records of each inspection, noting any issues found and actions taken. This documentation can be invaluable for tracking the valve’s condition over time.

Determining how often to conduct inspections depends on several factors:

- Operating Conditions: Valves in harsher environments may require more frequent inspections.

- Usage Frequency: Valves that are used regularly should be inspected more often than those that are rarely operated.

- Manufacturer Recommendations: Always refer to the manufacturer’s guidelines for specific inspection intervals.

It is essential that personnel conducting inspections are adequately trained. Understanding the specific requirements of backup gate valves and having the ability to identify potential issues is crucial for effective maintenance. Regular training sessions can help keep staff updated on best practices and new technologies.

In summary, routine inspections are a vital aspect of maintaining backup gate valves. By following the outlined procedures and ensuring proper training, you can enhance the reliability and lifespan of these critical components. Regular inspections not only protect your investment but also contribute to the overall safety and efficiency of your systems.

Cleaning and Lubrication Techniques

Maintaining backup gate valves is crucial for their optimal performance and longevity. One of the most important aspects of this maintenance is cleaning and lubrication. This section outlines effective techniques to ensure that your backup gate valves remain in top condition.

Regular cleaning of backup gate valves helps to prevent the accumulation of dirt, debris, and corrosive substances that can lead to malfunction. Neglecting to clean these components can result in blockages and reduced efficiency, ultimately leading to costly repairs or replacements.

- Visual Inspection: Before starting the cleaning process, conduct a thorough visual inspection to identify any visible dirt or corrosion.

- Use of Appropriate Cleaning Agents: Select a cleaning agent that is compatible with the materials of the valve. Avoid harsh chemicals that can cause damage.

- Gentle Scrubbing: Use a soft brush or cloth to scrub away dirt and grime without scratching the valve surfaces.

- Rinsing: Rinse the valves with clean water to remove any residual cleaning agents. Ensure that no moisture remains in crevices.

Proper lubrication is essential to ensure smooth operation and prevent wear and tear. Here are some best practices for lubricating backup gate valves:

- Select the Right Lubricant: Use a lubricant that is specifically designed for use with gate valves. Look for options that offer corrosion resistance and can withstand varying temperatures.

- Application: Apply the lubricant evenly to all moving parts, including the stem and seals. Avoid over-lubricating, as this can attract dirt and debris.

- Frequency of Lubrication: Establish a regular lubrication schedule based on usage and environmental conditions. For valves in harsh environments, consider increasing the frequency.

To achieve the best results, it is essential to avoid common pitfalls:

- Using Improper Cleaning Methods: Avoid abrasive materials that can damage the valve surfaces.

- Neglecting to Dry: Ensure that valves are completely dry after cleaning to prevent corrosion.

- Skipping Lubrication: Do not overlook lubrication; it is as crucial as cleaning for the longevity of your valves.

By implementing these cleaning and lubrication techniques, you can significantly enhance the performance and lifespan of your backup gate valves. Regular maintenance not only ensures reliability but also saves costs in the long run.

What Common Mistakes Should Be Avoided When Storing Backup Gate Valves?

When it comes to the storage of backup gate valves, avoiding common mistakes can significantly enhance their effectiveness and longevity. This section identifies frequent pitfalls and provides guidance on how to steer clear of them, ensuring that your valves remain in optimal condition for their intended applications.

- Neglecting Environmental Factors: One of the most critical mistakes is failing to consider environmental conditions. Backup gate valves should be stored in a controlled environment where temperature and humidity levels are monitored. Excessive heat can lead to material degradation, while high humidity can foster corrosion.

- Improper Handling and Transportation: Mishandling during transportation can cause physical damage to the valves. Always use appropriate lifting techniques and ensure that valves are securely packaged to prevent movement during transit. Using protective packaging can mitigate the risk of scratches and dents.

- Inadequate Cleaning Before Storage: Storing valves without proper cleaning can trap contaminants that may lead to corrosion or other forms of damage. Always clean valves thoroughly before storage, removing any dirt, grease, or debris that could compromise their integrity.

- Ignoring Manufacturer Guidelines: Each valve may have specific storage requirements as outlined by the manufacturer. Ignoring these guidelines can lead to improper storage practices. Always refer to the manufacturer’s manual for tailored storage recommendations.

- Failing to Inspect Regularly: Regular inspections are essential for identifying potential issues before they escalate. Neglecting to conduct routine checks can lead to unnoticed damage that may render the valves unusable when needed. Schedule periodic inspections to assess the condition of stored valves.

- Overcrowding Storage Areas: Overloading storage spaces can lead to accidental damage. Valves should be stored in a manner that allows for adequate space between each unit, reducing the risk of impacts and ensuring ease of access for inspections.

- Using Incorrect Packaging Materials: The choice of packaging materials can greatly affect the condition of stored valves. Avoid using materials that may retain moisture or deteriorate over time. Instead, opt for breathable packaging that allows for air circulation while protecting against dust and debris.

By recognizing and avoiding these common mistakes, you can enhance the storage practices for backup gate valves. Proper attention to environmental factors, handling procedures, and regular maintenance will ensure that your valves remain in excellent condition, ready for immediate use when required.

Neglecting Environmental Factors

When it comes to the longevity and performance of backup gate valves, can have severe consequences. The conditions in which these valves are stored and operated play a crucial role in their overall functionality and lifespan. This section explores the critical importance of monitoring environmental conditions to prevent premature valve failure.

One of the primary environmental factors to consider is temperature. Extreme temperatures can lead to material degradation, affecting the integrity of the valve. For instance, high temperatures can cause the rubber seals to harden and crack, leading to leaks. Conversely, low temperatures can make materials brittle, increasing the risk of fractures. It is essential to maintain a stable temperature range, ideally between 50°F and 85°F, to ensure optimal performance.

Another significant factor is humidity. Excess moisture in the storage environment can lead to corrosion, especially for metal components. Corrosion not only weakens the structure of the valve but can also cause operational failures when the valve is put to use. To combat this, it is advisable to use desiccants in storage areas and monitor humidity levels regularly. Keeping humidity below 60% can significantly reduce the risk of corrosion.

Additionally, air quality is often overlooked but is equally important. Contaminants in the air, such as dust and chemicals, can settle on the valve surfaces, leading to wear and tear. Implementing air filtration systems in storage areas can help maintain clean air, thus prolonging the life of backup gate valves.

Furthermore, vibration and physical disturbances should not be ignored. Storing valves in high-traffic areas can expose them to vibrations that may lead to misalignment or damage over time. It is crucial to store valves in a stable environment, away from heavy machinery and frequent movement.

To summarize, monitoring environmental factors such as temperature, humidity, air quality, and physical disturbances is vital for preserving the integrity of backup gate valves. By taking these precautions, you can prevent premature valve failure and ensure that your equipment remains functional and reliable for years to come.

In conclusion, understanding and actively managing the environmental factors surrounding backup gate valves is essential for their optimal performance. Regular assessments and adjustments to storage conditions will not only enhance the longevity of the valves but also save costs associated with premature replacements and maintenance.

Improper Handling and Transportation

When it comes to backup gate valves, ensuring their safety during handling and transportation is critical to maintaining their integrity and functionality. Improper handling can lead to significant damage, resulting in costly repairs and operational disruptions. In this section, we will explore the best practices for safe handling and transportation of backup gate valves.

Understanding the importance of safe handling and transportation is essential for anyone involved in the maintenance and management of backup gate valves. These components are often made from materials that can be susceptible to physical damage and corrosion if not handled correctly. Mishandling can lead to:

- Cracks and Deformations: Improper lifting techniques can cause structural damage.

- Corrosion: Exposure to moisture and contaminants can accelerate the deterioration process.

- Operational Failures: Damaged valves can lead to system failures, causing downtime and increased costs.

To ensure the longevity and performance of backup gate valves, it is crucial to follow best practices during handling:

- Use Proper Lifting Techniques: Always lift valves using appropriate equipment and techniques to avoid stress on the body of the valve.

- Wear Protective Gear: When handling heavy or sharp objects, appropriate personal protective equipment (PPE) should be worn to ensure safety.

- Inspect Before Moving: Always conduct a visual inspection before transportation to identify any pre-existing damage.

Transporting backup gate valves requires careful planning to avoid damage:

- Secure Packaging: Use robust packaging materials such as foam or bubble wrap to cushion the valves during transport.

- Label Clearly: Ensure that packaging is labeled with handling instructions to inform transport personnel of the necessary precautions.

- Avoid Extreme Conditions: Transport valves in climate-controlled environments to prevent exposure to moisture and extreme temperatures.

Being aware of common mistakes can help prevent damage:

- Neglecting to Secure Valves: Failing to secure valves can lead to movement during transport, causing potential damage.

- Using Inadequate Equipment: Always use appropriate lifting and transportation equipment to avoid accidents and damage.

- Ignoring Manufacturer Guidelines: Each valve type may have specific handling and transportation requirements; always refer to the manufacturer’s instructions.

In summary, the safe handling and transportation of backup gate valves are vital for preserving their functionality and extending their lifespan. By adhering to the best practices outlined above, individuals and organizations can minimize the risk of damage and ensure that their systems operate smoothly and efficiently.

When Should You Replace Backup Gate Valves?

Recognizing the right time to replace backup gate valves is crucial for maintaining the reliability and efficiency of your plumbing or industrial systems. Failure to address worn-out valves can lead to significant operational issues, including leaks and system failures. This section will guide you through the signs of wear and the factors to consider when determining replacement timelines.

Identifying the signs of wear on backup gate valves is essential for preventing unexpected failures. Here are some common indicators that a valve may need replacement:

- Corrosion: Visible rust or corrosion on the valve body or components can compromise functionality.

- Leaks: Any signs of leaking, whether from the valve itself or surrounding connections, indicate that replacement is necessary.

- Difficulty in Operation: If the valve is hard to open or close, it may be time for a replacement.

- Unusual Noises: Grinding or squeaking sounds during operation can signal internal damage.

- Age of the Valve: If the valve is significantly older than its expected lifespan, proactive replacement is advisable.

When it becomes clear that a backup gate valve needs replacing, understanding your options is critical. There are various types of backup gate valves available, each suited for different applications:

- Manual Gate Valves: Ideal for applications requiring manual control.

- Electric Gate Valves: Suitable for automated systems, providing remote operation capabilities.

- Pneumatic Gate Valves: Often used in systems requiring quick actuation.

Consider factors such as material compatibility, pressure ratings, and environmental conditions when selecting a new valve. Consulting with a professional can help ensure you choose the right type for your specific needs.

Establishing a timeline for replacement is equally important. Regular inspections should be scheduled, allowing you to monitor the condition of your backup gate valves. If any of the signs mentioned earlier are observed, it’s wise to prioritize replacement to avoid system downtime.

Additionally, consider the operational demands on your system. If your facility experiences high usage or operates under extreme conditions, more frequent evaluations may be necessary. Keeping a maintenance log can help track the performance and condition of each valve, aiding in timely decision-making regarding replacements.

In summary, recognizing the signs of wear and damage in backup gate valves is essential for ensuring system reliability. By being proactive and informed about replacement options and timelines, you can maintain optimal performance and avoid costly disruptions. Regular inspections and a keen awareness of the operational environment will serve as your best tools in managing the lifecycle of backup gate valves.

Signs of Wear and Damage

Recognizing the signs of wear and damage in backup gate valves is crucial for maintaining system integrity and preventing failures. Early identification of these indicators can save time, money, and resources by allowing for timely replacements. Below are some common signs that suggest a gate valve may need to be replaced:

- Visible Corrosion: One of the first signs of wear is the presence of rust or corrosion on the valve body. This can weaken the material, leading to leaks or complete failure.

- Difficulty in Operation: If the valve becomes hard to open or close, it may indicate internal wear or buildup of debris. This can hinder performance and signal that the valve is nearing the end of its usable life.

- Leaks: Any signs of leakage around the valve stem or body are a clear indication that the valve may be compromised. Even small leaks can escalate into larger issues if not addressed promptly.

- Unusual Noises: Grinding, squeaking, or rattling noises during operation can indicate mechanical wear or damage to the internal components of the valve.

- Inconsistent Flow: If there are fluctuations in flow rates when the valve is in the open position, it might mean that the valve is not sealing properly due to wear.

- Physical Damage: Cracks, dents, or other physical deformities can compromise the integrity of the valve. Such damage often necessitates immediate replacement to avoid failure.

- Age of the Valve: Even if a valve appears to be functioning well, consider its age. Many valves have a recommended lifespan, and exceeding this period can increase the risk of unexpected failures.

- Changes in Pressure: Sudden changes in pressure readings can signal that the valve is not functioning correctly. This could be due to internal wear or blockage, necessitating a thorough inspection.

In summary, regular inspections and awareness of these signs can help in making informed decisions about the replacement of backup gate valves. By being proactive, you can ensure the reliability and safety of your systems, preventing costly downtime and repairs.

Evaluating Replacement Options

When it comes to the replacement of backup gate valves, understanding your options is not just beneficial; it is essential for ensuring system reliability and efficiency. This section delves into the various types of backup gate valves available in the market, their unique applications, and how to choose the right one for your needs.

- Wedge Gate Valves: These are commonly used in high-pressure applications due to their robust design. They provide a tight seal and are suitable for both on-off and throttling services.

- Parallel Gate Valves: Ideal for low-pressure systems, these valves have two parallel discs that open and close simultaneously. They are often used in water and wastewater applications.

- Knife Gate Valves: These valves are designed for slurries and other viscous fluids. The blade-like gate cuts through the material, making them perfect for handling tough substances.

- Electric Gate Valves: For automated systems, electric gate valves offer the advantage of remote operation. They are commonly used in industrial settings where precise control is necessary.

- Check Gate Valves: These valves prevent backflow in pipelines. They are essential in systems where fluid direction is critical to prevent damage or contamination.

Selecting the appropriate backup gate valve requires careful consideration of several factors:

- Application Requirements: Assess the specific needs of your system, including pressure, temperature, and the type of fluid being handled.

- Material Compatibility: Ensure that the valve materials are compatible with the fluids they will encounter to prevent corrosion and degradation.

- Size and Configuration: The size of the valve must match the pipeline dimensions to ensure proper flow and prevent bottlenecks.

- Maintenance Needs: Some valves require more maintenance than others. Choose a valve that fits your maintenance capabilities and schedules.

Understanding the benefits of different types of backup gate valves can aid in making an informed decision:

- Wedge Gate Valves: Known for their durability, they can withstand high pressures and provide a reliable seal.

- Parallel Gate Valves: Their design allows for minimal pressure drop, making them efficient for water distribution.

- Knife Gate Valves: Their unique design allows for easy cleaning and maintenance, particularly in slurry applications.

- Electric Gate Valves: Automation capabilities enhance operational efficiency and reduce manual labor.

- Check Gate Valves: Essential for protecting equipment from damage caused by backflow, they provide peace of mind in system integrity.

Regular evaluations of your backup gate valves are crucial. If you notice frequent leaks, reduced performance, or increased maintenance costs, it may be time to consider upgrading. Additionally, advancements in valve technology may offer improved efficiency and reliability that older models cannot provide.

In conclusion, evaluating replacement options for backup gate valves involves understanding the types available, their benefits, and how they fit into your specific application. By taking the time to assess your needs and the options at hand, you can make a decision that enhances the performance and longevity of your system.

Frequently Asked Questions

- What is the best way to store backup gate valves?

To store backup gate valves properly, ensure they are placed in a cool, dry environment. It’s essential to control the temperature and humidity levels to prevent degradation and corrosion. Using appropriate packaging materials can also help protect them from physical damage.

- How often should I inspect my backup gate valves?

Regular inspections should be conducted at least once every six months. This routine check helps identify any potential issues early on, ensuring that your valves remain in optimal condition and function effectively when needed.

- What are common mistakes to avoid when maintaining backup gate valves?

Common mistakes include neglecting environmental factors, such as humidity and temperature, which can lead to corrosion. Additionally, improper handling during transportation can cause physical damage. Always follow best practices to ensure longevity.

- How do I know when to replace my backup gate valves?

Look for signs of wear and damage, such as leaks or difficulty in operation. If the valve shows significant wear or has been in service for a long time, it might be time for a replacement to maintain system reliability.